Lean & Business Process

What Do We Mean By “Lean”?

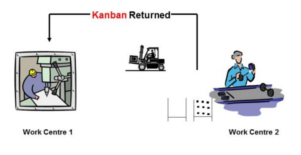

One of the most-often quoted terms in Operations Management, Lean embraces a host of other techniques. It owes its existence to John Krafcik, a researcher on the MIT project studying Japan’s automotive success in the 1980s. People had initially seen Japanese manufacturing apparently running without inventory and everything arriving ‘Just in Time’ as being due to a simple yellow card called a kanban to trigger all replenishment.

Of course, the early assessments had got it the wrong way round. The kanban was the last stage in Japanese success. It worked because of all the steps that had been taken within the overall process to guarantee that when the card was launched, items were produced quickly, at guaranteed quality, without the encumbrances of needing to tie up plant with ‘economic’ batch quantities, and so on. Krafcik recognised that the businesses he was researching ran without waste, which he contrasted to the fat-free or ‘Lean’ of world-class athletes.

The Elements of Lean

There really are too many tools and techniques within the Lean framework to be listed in an introduction to the Institute’s forum. As well as the specific approaches like the 5S Housekeeping tool and Quality Circles – in which production team leaders can summon senior management to multi-functional meetings to genuinely address the root causes of problems, with tasks allocated to anybody in the session with no allowance made for an individual’s standing if he or she is the right person to pick something up – there are the cultural aspects of the approach to be understood.

In addition, Lean can apparently be adopted in two ways – that of Kaizen (continuous improvement) or Kaikaku (step change).

The Forum

The Forum will provide the opportunity to help each other develop improved understanding of the attack on waste.

The Forum Leader

Ian Henderson is an interim manager and consultant who has led improvement in a number of businesses since first joining the Institute in its days as the British Production and Inventory Control Society and being awarded its Graduate Diploma early in his career. He has held several Operations Director roles in companies making engineered products to order – proving that Lean is not just a tool for automotive companies.

Ian Henderson is an interim manager and consultant who has led improvement in a number of businesses since first joining the Institute in its days as the British Production and Inventory Control Society and being awarded its Graduate Diploma early in his career. He has held several Operations Director roles in companies making engineered products to order – proving that Lean is not just a tool for automotive companies.

He has a black belt in judo and various arthritic joints from being thrown around dojos up and down the country. He now enjoys seeing others collecting bruises as a season ticket holder of Sale Sharks Rugby Club.